Contact Us

News content

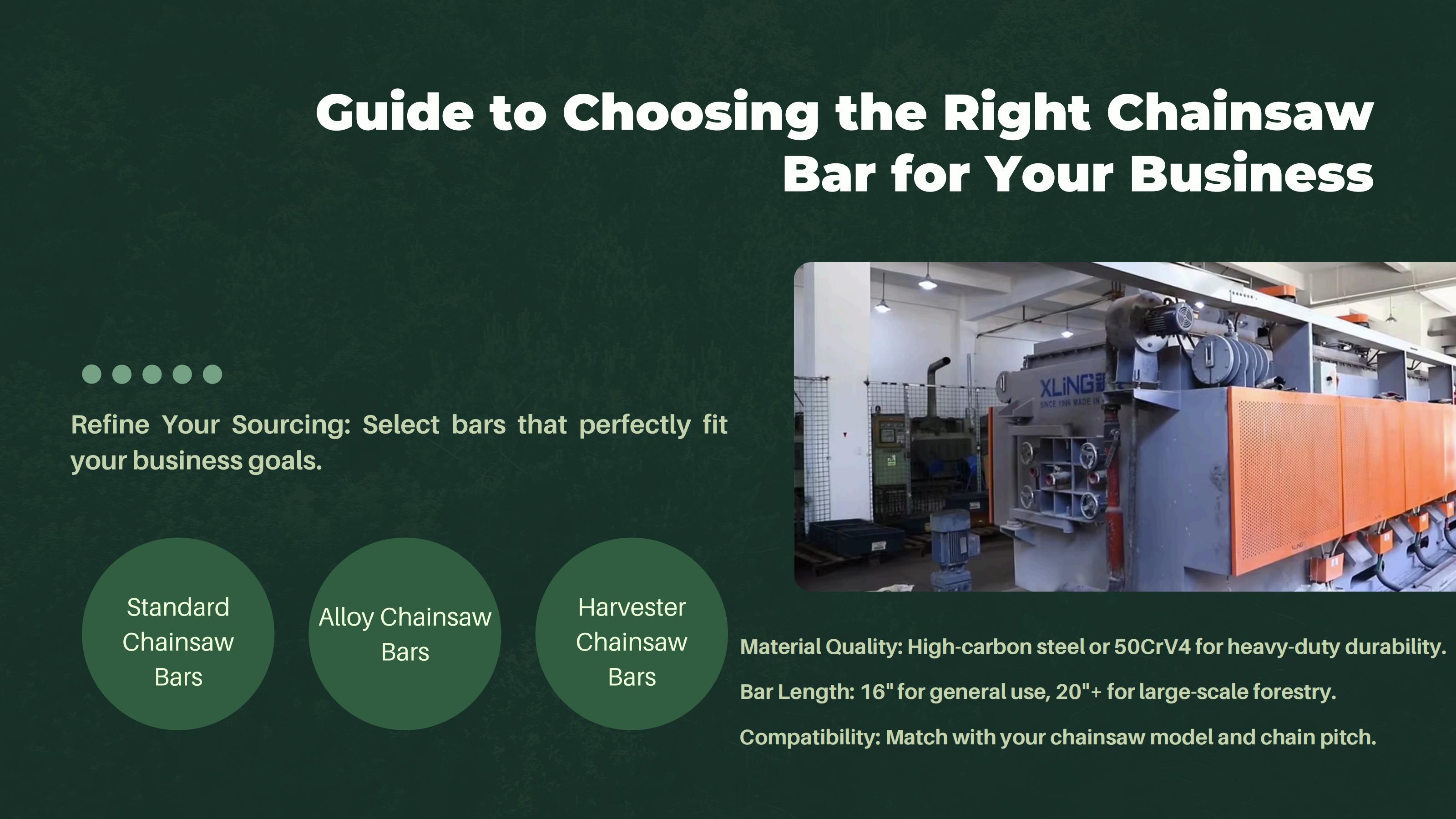

When it comes to tackling heavy-duty cutting tasks with precision and efficiency, selecting the ideal chain saw guide bar is pivotal. The right guide bar not only enhances the performance of your chainsaw but also ensures safety and durability. This comprehensive guide will navigate you through the critical considerations, types, maintenance, and tips for purchasing a chain saw guide bar that perfectly suits your needs.

The chain saw guide bar, often regarded as the backbone of the chainsaw, holds the cutting chain in place and dictates the cutting capacity. It plays a vital role in determining the overall efficiency and functionality of the chainsaw. Understanding the components and functionalities of a guide bar is crucial before delving into the selection process.

The chain saw guide bar comprises essential components that collaborate to deliver optimal cutting performance:

1. Bar Body: The main structural component of the guide bar, typically made from high-grade steel or lightweight alloys, determines the length and thickness of the bar.

2. Bar Tip: The extremity of the guide bar, featuring either a sprocket or a replaceable nose, ensures smooth chain movement.

3. Guide Bar Groove: A specialized groove in the bar where the cutting chain rests and moves during operation.

4. Chain Tensioner Hole: Located near the base of the bar, it allows for adjustments in the chain tension, ensuring proper functionality.

Understanding the diverse range of guide bars available in the market is crucial to make an informed decision that aligns with your cutting needs. Different types of guide bars cater to varying cutting applications and chainsaw models.

Standard guide bars are the most common and versatile type, suitable for general-purpose cutting tasks. They come in various lengths, typically ranging from 12 to 20 inches, catering to different chainsaw sizes and power capacities.

Designed for heavy-duty and prolonged use, professional guide bars are constructed using high-quality materials, providing enhanced durability and precision. They often feature specialized coatings for reduced friction and increased longevity.

Carving guide bars are shorter in length and specifically crafted for intricate and detailed wood carving tasks. Their compact design allows for greater maneuverability and precision when working on small projects.

Laminated guide bars are constructed using multiple layers of metal, making them lightweight yet durable. They are suitable for less demanding cutting tasks and are commonly found in consumer-grade chainsaws.

Selecting the perfect chain saw guide bar involves assessing several critical factors to ensure compatibility, efficiency, and safety during operation.

The length of the guide bar significantly impacts the cutting capacity and maneuverability of the chainsaw. Longer bars are suitable for larger jobs requiring deeper cuts, while shorter bars offer increased control and precision for smaller tasks.

Not all guide bars are compatible with every chainsaw model. Ensure compatibility by checking the chainsaw's specifications and recommendations provided by the manufacturer.

Consider the type of cutting tasks you'll undertake regularly. Heavy-duty tasks necessitate a robust and durable guide bar, while smaller projects may benefit from a more maneuverable and lightweight option.

Different guide bars require varying levels of maintenance. Some may need frequent lubrication or adjustments, while others offer self-lubricating or low-maintenance features.

Prioritize guide bars equipped with safety features such as reduced kickback, anti-vibration technology, and built-in chain brakes to ensure safer operation.

Regular maintenance is crucial to prolong the lifespan and ensure optimal performance of your chain saw guide bar.

After each use, clean the guide bar thoroughly to remove debris, sawdust, and resin buildup. Use a specialized cleaner or a brush to prevent corrosion and maintain the bar's functionality.

Proper lubrication is essential for smooth chain movement and reducing friction. Apply chain oil regularly to the guide bar groove to ensure efficient operation and prevent premature wear.

Monitor and adjust the chain tension regularly to prevent sagging or excessive tightness, which can lead to reduced cutting efficiency and potential safety hazards.

Equipped with the necessary knowledge, consider these additional tips to make an informed purchase decision:

1. Research Brands: Explore reputable brands known for producing high-quality guide bars that align with your requirements.

2. Read User Reviews: Utilize online resources to read user reviews and gather insights into the performance and durability of specific guide bars.

3. Consult Experts: Seek advice from professionals or experts in the field to gain valuable recommendations based on your cutting needs.

4. Warranty and Support: Prioritize guide bars that come with a warranty and reliable customer support for any potential issues or queries.

Selecting the perfect chain saw guide bar involves a comprehensive understanding of your cutting requirements, compatibility with your chainsaw, and consideration of various features offered by different types of guide bars. By taking into account these factors and maintenance practices, you can ensure efficient, safe, and prolonged usage of your chainsaw for diverse cutting tasks. Invest time in research, consult experts, and prioritize quality when making your purchase to maximize the performance and longevity of your chain saw guide bar.

In conclusion, the right chain saw guide bar is not just an accessory but a crucial component that enhances the functionality and safety of your chainsaw, allowing you to accomplish cutting tasks with precision and ease.

More

When it comes to choosing the right chainsaw harvester bar for your needs, understanding the importance of different types, sizes, and functionalities is crucial. From stability to cutting efficiency, every detail can have a significant impact on your work. This article aims to provide you with a comprehensive guide to help you become well-versed in selecting and purchasing chainsaw harvester bars.

Chainsaw bars, often referred to as guide bars, are an integral component of any chainsaw. These sturdy, elongated metal bars serve as the guide for the cutting chain, dictating the precision and efficiency of the saw. Whether you're a seasoned professional or a DIY enthusiast, understanding the nuances of chainsaw bars is crucial in selecting the right one for your cutting needs.

Chainsaw bars are fundamental components of any chainsaw, playing a crucial role in determining the tool's performance, efficiency, and versatility. Understanding the intricacies of chainsaw bars is essential for making an informed purchase decision, ensuring safety, and optimizing your cutting experience.

Chainsaw bars come in various sizes to suit different cutting needs.Common chainsaw bar lengths include 12 inches, 14 inches, 16 inches, 18 inches, 20 inches, 24 inches, 28 inches, and even longer. The choice of bar length depends on the type of cutting tasks you plan to perform. Smaller bars are suitable for light-duty tasks and precision cutting, while longer bars are designed for heavy-duty and professional applications. It's important to select the right bar length that matches your specific cutting requirements and the power of your chainsaw.Qirui’s best-selling sizes: 48, 52, 72, and 76-Inch Chainsaw Bars. Leave an email or WhatsApp in the comments section and our business manager will send you the details!

More

Email: qirui@qiruibar.com

Tel:0086-571-82308666

Add: No. 390, Xiangdafang Industrial Park, Wenyan Street, Xiaoshan District,Hangzhou,Zhejiang,China

Website: www.qiruibar.com

Contact Us

Contact Us