Contact Us

News content

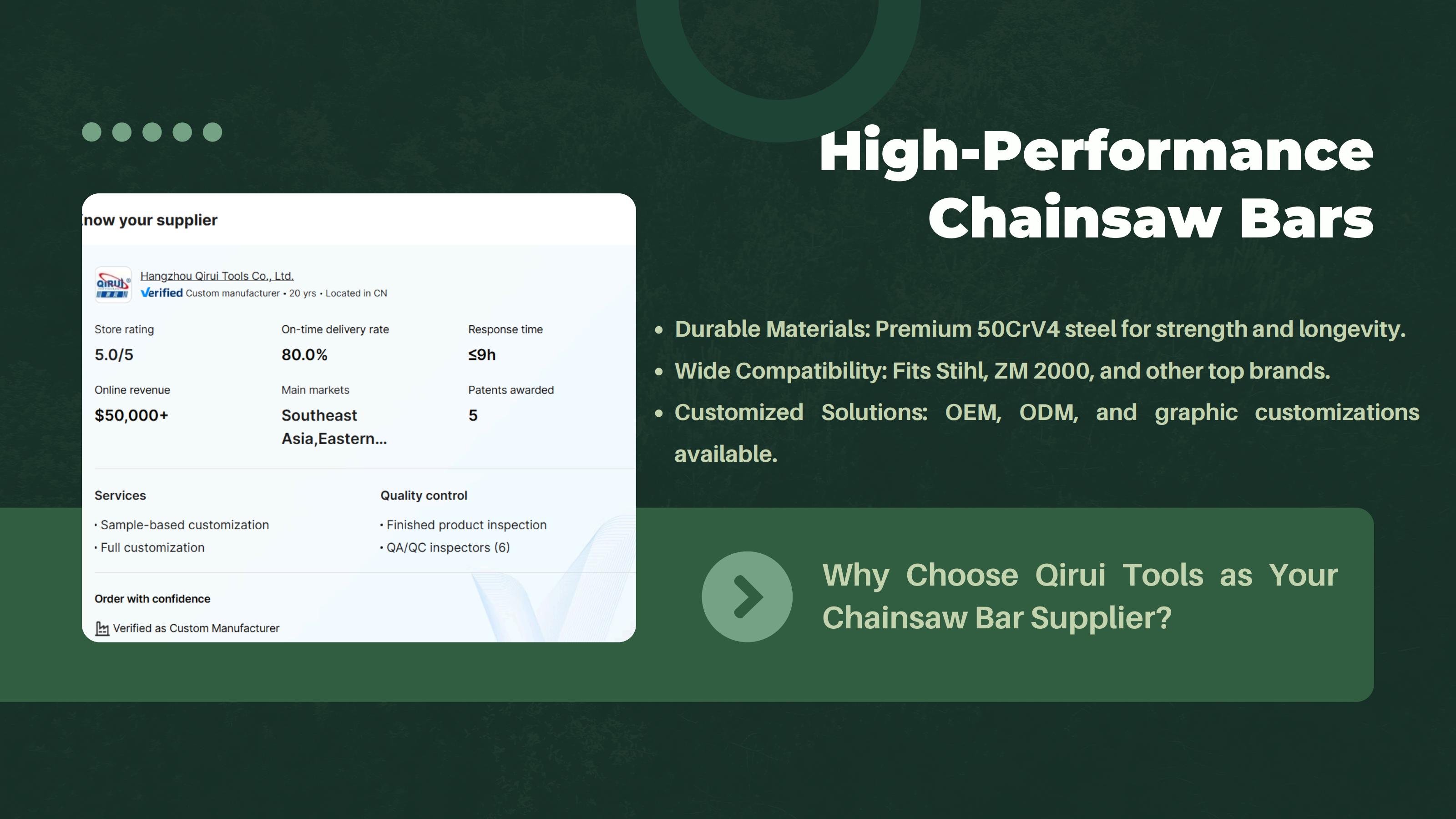

When it comes to choosing the right chainsaw harvester bar for your needs, understanding the importance of different types, sizes, and functionalities is crucial. From stability to cutting efficiency, every detail can have a significant impact on your work. This article aims to provide you with a comprehensive guide to help you become well-versed in selecting and purchasing chainsaw harvester bars.

Chainsaw harvester bars are fundamental to efficient cutting operations. These bars are intricately designed to withstand rigorous usage in demanding environments. Before investing in one that suits your specific requirements, it's essential to comprehend their construction, functionalities, and variations.

Tracing the evolution of chainsaw harvester bars unveils a fascinating journey of innovation and engineering excellence. From primitive designs of the past to today's cutting-edge technology, each iteration has aimed to enhance performance and productivity.

These bars are the traditional choice, offering a balance between maneuverability and stability during cutting tasks.

Designed for heavy-duty usage, these bars boast superior durability and cutting precision, making them ideal for commercial forestry operations.

Tailored to specific tasks, these bars cater to unique cutting requirements, such as felling large trees or precision cutting in confined spaces.

The length of the chainsaw harvester bar significantly impacts its cutting capacity and maneuverability. Understanding the relationship between bar length and efficiency is vital for optimizing your workflow.

The thickness of the bar, known as the gauge, determines its stability and resilience. Choosing the appropriate gauge ensures safety and operational efficiency.

Different materials, such as steel alloys or titanium, affect the bar's weight, durability, and resistance to wear. Choosing the right material is crucial for longevity and performance.

Bars for forestry work require robustness, precision, and the ability to withstand prolonged use in challenging terrains.

Bars for arborists need versatility and ease of maneuverability to navigate branches and perform intricate cuts efficiently.

In these settings, bars need to handle diverse materials and cutting angles, emphasizing adaptability and durability.

Proper maintenance is essential to prolong the life of your chainsaw harvester bar. Regular cleaning, lubrication, and ensuring correct tension contribute significantly to its longevity and efficiency.

From advanced coating materials to ergonomic designs, continuous innovations have revolutionized chainsaw harvester bars. Keeping up with the latest technological advancements can lead to improved performance and user comfort.

Mastering the art of selecting and utilizing chainsaw harvester bars empowers professionals to enhance productivity while ensuring safety and precision. By understanding their nuances, applications, and maintenance requirements, individuals can make informed decisions when purchasing these essential tools.

More

Chainsaw bars, often referred to as guide bars, are an integral component of any chainsaw. These sturdy, elongated metal bars serve as the guide for the cutting chain, dictating the precision and efficiency of the saw. Whether you're a seasoned professional or a DIY enthusiast, understanding the nuances of chainsaw bars is crucial in selecting the right one for your cutting needs.

Chainsaw bars are fundamental components of any chainsaw, playing a crucial role in determining the tool's performance, efficiency, and versatility. Understanding the intricacies of chainsaw bars is essential for making an informed purchase decision, ensuring safety, and optimizing your cutting experience.

Chainsaw bars come in various sizes to suit different cutting needs.Common chainsaw bar lengths include 12 inches, 14 inches, 16 inches, 18 inches, 20 inches, 24 inches, 28 inches, and even longer. The choice of bar length depends on the type of cutting tasks you plan to perform. Smaller bars are suitable for light-duty tasks and precision cutting, while longer bars are designed for heavy-duty and professional applications. It's important to select the right bar length that matches your specific cutting requirements and the power of your chainsaw.Qirui’s best-selling sizes: 48, 52, 72, and 76-Inch Chainsaw Bars. Leave an email or WhatsApp in the comments section and our business manager will send you the details!

When it comes to cutting power and efficiency, having the right tools can make all the difference. If you're looking for a guide bar that can maximize your cutting power, then the 880 Long Chainsaw Guide Bar is a perfect choice.

More

Email: qirui@qiruibar.com

Tel:0086-571-82308666

Add: No. 390, Xiangdafang Industrial Park, Wenyan Street, Xiaoshan District,Hangzhou,Zhejiang,China

Website: www.qiruibar.com

Contact Us

Contact Us