Contact Us

News content

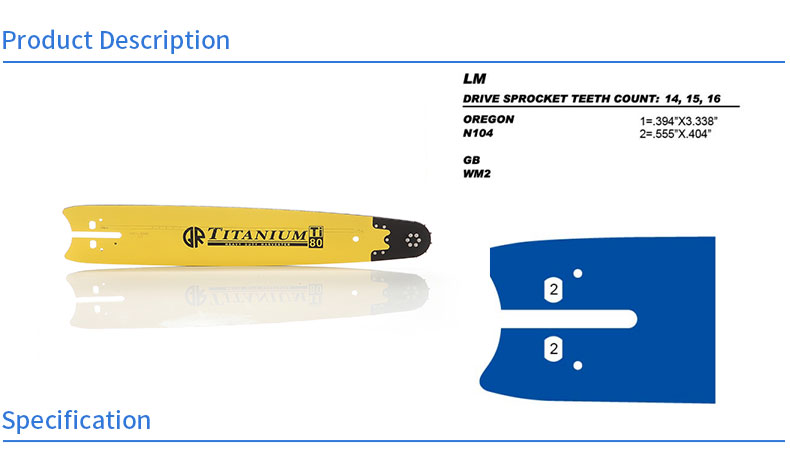

The Harvester Processor Bar 75cm MAYA is a robust and durable component designed for heavy-duty chainsaw applications in industries like forestry and logging. Manufactured to the highest standards with foreign enterprise heat treatment, this bar ensures exceptional strength and longevity, perfect for extended use in harsh conditions. With customization options available, this chainsaw part can be tailored to meet specific operational needs.

Explore more about MAYA 25” Solid Harvester Sprocket Nose Bar TSfor additional size and application options.

Designed to fit a variety of chainsaws, the Harvester Processor Bar is highly adaptable to different engine displacements and power configurations.

| Engine Displacement | Any type |

|---|---|

| Power | Any type |

| Place of Origin | Zhejiang, China |

|---|---|

| Power Source | Petrol/Gasoline |

| Grade | Industrial |

| Warranty | None |

| Model Number | MF25-80TN |

| Saw Chain Pitch | .404 |

| Saw Chain Gauge | .080 |

| Saw Chain Color | Black, blue, or OEM |

| Saw Chain Certificate | CE, UL, CUL |

| Heat Treatment | Foreign enterprise process |

| Saw Chain Sample | Available for testing |

| OEM Service | Available |

| Transport | By air, sea, or land |

Our chainsaw parts are carefully packaged to ensure safe delivery, with customizable packaging options based on customer needs.

| Packaging Details | White box, color box, blister packing, or customized |

|---|---|

| Port | Shanghai/Ningbo |

| Selling Units | Single item |

| Single Package Size | 25x25x25 cm |

| Single Gross Weight | 10.000 kg |

| Supply Ability | 6000 pieces per day |

| Quantity (Pieces) | Lead Time (Days) |

|---|---|

| 1 - 1 | 15 |

| > 1 | To be negotiated |

We are the top manufacturer with a complete product series, offering a wide range of chainsaw guide bars and other parts for industrial applications.

Our products are made with imported raw materials and automatic production lines, ensuring both quality and production capacity. Every product meets the CE, UL, and CUL standards, giving our clients confidence in the reliability of our chainsaw parts.

With trusted brands like MAYA and QIRUI, we have established a solid reputation globally. Our products are recognized for their high performance and dependability in challenging environments.

Our chainsaw parts, including the Harvester Processor Bar, undergo rigorous testing, with results supported by comparison testing reports from satisfied clients. This ensures superior performance and durability.

We offer comprehensive OEM & ODM services, customizing products to meet your specific needs. Whether based on your sample or technical drawings, we can tailor our solutions to your requirements.

Learn more about our MAYA 3/4” Harvester Replaceable- Nose Barfor more specialized applications.

More

Explore the differences between steel and alloy materials for guide bars and saw chains. Learn about hardness, strength, and corrosion resistance to make the best choice for your chainsaw needs.

Learn essential maintenance practices for guide bars and saw chains to maximize chainsaw performance and prolong working life. Explore tips for cleaning, lubrication, tension adjustment, and rotation to optimize cutting efficiency and safety.

Discover how to enhance your chainsaw's cutting efficiency by selecting the right guide bar and saw chain. Learn about different types, maintenance tips, and key factors for optimizing performance.

Discover the differences between solid and laminated guide bars for chainsaws. Explore the pros and cons of each type and learn how to choose the right option for your cutting needs.

Discover comprehensive steps for inspecting and maintaining guide bars and saw chains to enhance chainsaw longevity and performance. Learn essential practices for wear detection, damage prevention, and replacement to ensure optimal cutting efficiency.

Email: qirui@qiruibar.com

Tel:0086-571-82308666

Add: No. 390, Xiangdafang Industrial Park, Wenyan Street, Xiaoshan District,Hangzhou,Zhejiang,China

Website: www.qiruibar.com

Contact Us

Contact Us